| Motors from

three and two port Sunvic actuators. Never attempt to force these output spindles around by hand or using tools! The motor output spindles should rotate slowly when the motor is connected to mains voltage. These motors will overheat if left connected for more than a few tens of minutes. The motor gearbox cover plate is securely staked in position at eight locations around its circumference. The only safe way to remove the cover plate is to use a file or an angle grinder to destroy the staking. |

|

|

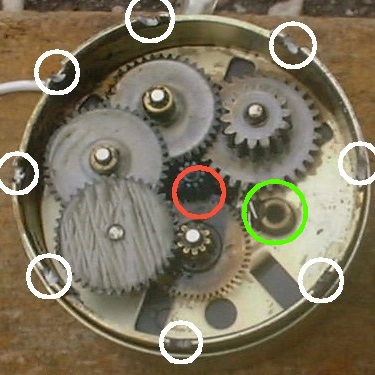

These Sunvic

motors can be taken to pieces - but not easily put back together again!! The white circles show where the staking has been removed by careful use of a high speed angle grinder fitted with a very thin cutting disc. The red circle shows the failed plastic gearwheel (see close-up photo below) and the green circle shows the bush for the output spindle. These are very well made motors - but they either run backwards or fail completely when the grease starts to dry out after a few years' use. |

| The gearbox

cover plate and output gear wheel. The grease in this motor first liquefied owing to the motor running for hours and overheating. Then the grease solidified as it 'boiled off', leaving all the gearwheel spindles firmly locked in a thick treacle-like 'goo'. Which happened first is unclear - either the plastic gearwheel failed for some other reason - and then the motor overheated and the grease solidified, or the overheating and increased viscosity of the grease caused overloading which caused the gearwheel to fail. In all, a sorry end to an almost new Sunvic actuator. Spare motors are not available - but are thrown away in their hundreds because of electronic failures. What a shame! |

|

| The failed

plastic gearwheel - this gear takes the high speed drive directly from the motor in the

centre of the unit. Plastic may be used for cheapness, because the gearing is very lightly

loaded here, or as a safety cut-out mechanism. Overheating might be better prevented using

a positive coefficient variable resistor or similar electronic device. Apart from all the gearwheels being very stiff to move, the motor assembly had no other faults. If the gearbox was lubricated with a more suitable type of grease a 20 or 30 year life could easily be anticipated. As it is, these motors sometimes fail after a few years - but not half as often as the electronic circuit boards! |

|

| The central

(blue) shaft is the motor output. The two lugs (pointing to 10 and 4 o'clock) are what

operate the 'kickback' mechanism if the motor starts in the wrong direction (which it will

do 50% of the time). Once the motor starts in the wrong direction (clockwise), the white plastic 'plate' rotates anticlockwise with the gearwheel (not shown) and the projecting 'stop' then impacts one of the blue lugs, kicking the motor in the opposite direction. It will then continue to run in this (correct) direction - anticlockwise. The clockwise motion of the gearwheel that sits on top of the white kickback 'plate' causes it to move out of the way of the blue lugs. It is a very neat design - but it needs either thin grease or oil to work properly. |

|

| The kickback mechanism

fails when the grease within the unit becomes sticky. This white plastic 'plate' became

glued to the metal surface upon which it was located. This prevented it from moving when

the motor started in the wrong direction. The mechanism is a neat design but like other aspects of these Sunvic valves, failures result from a lack of proper evaluation of how critical design parameters change over time - grease becomes thick and 'gums up' the gearboxes (and especially the kickback mechanism), and electronic circuits degrade so rendering the actuators useless after a year or three of service. In all - a great shame, the basic design concept offered so much potential for longevity. |