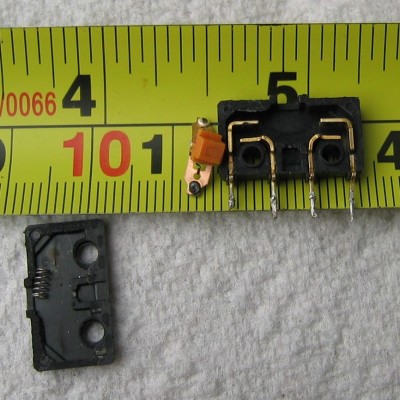

These are a very unusual 4 pin microswitch where one set of contacts are normally open (N/O) and the other set normally closed (N/C).

This example had only one 'burnt' contact and all 4 of the fixed pins (lugs) are still located correctly in the casing. Working from either end the pins can be denoted A B B A.

The contacts BB are N/C when the switch is 'at rest' - and AA are N/O. When the plunger is depressed, BB become open circuit and AA are connected. It is these outer (AA) contacts that overheat in MA1 actuators because the current loading is far greater than between BB.

In all cases of failures of the MA1 examined to date, it has been SW2 at fault. Based on a small sample therefore, the Drayton MA1 appears to have only one weak point. The rest of the design looks very robust. These special switches can easily be replaced but they are expensive. Ask me for details.

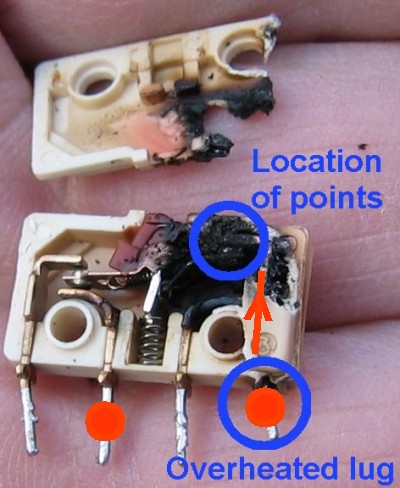

Also, one of the lugs became so hot that the solder connecting it to the circuit board melted allowing the fixed contact to move upwards (denoted by the red arrow) under slight pressure from the central spring that is normally kept in place under the pink plunger. With a current passing through AA (white wire to orange wire in the Drayton MA! actuator), the plunger would be depressed.

However, when the plunger became so hot that it partially melted and slipped to one side, spring pressure was transferred to act on the very hot contact lug. Because the solder was already molten and the lug surrounded by molten plastic, it was able to move. The contact points on this side of the switch are now located right at the top of the switch casing (compare to previous photo).

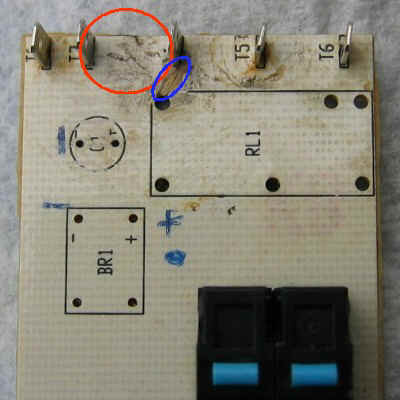

Tests have also confirmed that one mode of failure of the SW2 type of switch is for an A contact to become connected to a B contact - something that should never happen. In this particular example the two contacts denoted by red circles are electrically connected (albeit the resistance is a few thousand ohms owing to the contaminated contacts).

The power dissipation inside the switch to do this amount of damage would probably be around 5 to 10 watts.

In this orientation, any slight amount of water seeping from the valve gland tracks onto the circuit board and (via capillary action) under the relay (RL1). The circuit board becomes damp and conductive and high (mains) voltage flashes from one of the spade connectors to one of the low voltage coil connections of RL1 - the affected area is shown in blue. In this example the high voltage 'track' has been across the surface of the pcb and hence is easily visible. Sometimes the 'flashover' is within the thickness of the pcb or on the copper track side of the board, but the result is the same - instant destruction of this pin of the relay.

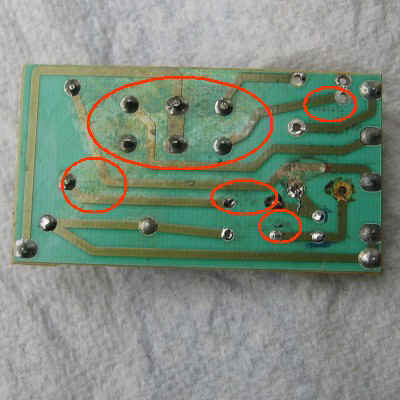

Additional carbonation and high voltage tracking within the thickness of the circuit board is shown in red and again is typical.

If these two port actuators are mounted with the cable pointing upwards there is less chance of water leaking onto this crucial area, and so the actuator may have a longer life - but not much longer if the whole board becomes at all damp.

Large areas of the board show the characteristic internal discoloration where mains voltage has started to track across the board. This board is at an early stage of failure - quite often the damage is more extensive before some part of the board either explodes or burns almost to a cinder - and at some point in the process the householder may notice that the actuator has stopped working!

The overall susceptibility of these circuit boards to moisture is one of the worst design features of the Sunvic 1801/1901 range of actuators because - short of making up a new board and placing all components apart from the two micro-switches and motor in a separate box outside the actuator - it is completely irreparable. However I have tested a new improved version of the 1801. A similar upgrade of the 1901 is not possible owing to its greater complexity.

For improved reliability, the old design of spring return 2301actuator can be fitted instead of an 1801 and these are almost immune to slight dampness caused by weeping valve spindles.

In this example however, a microswitch has overheated very badly and 'cooked' the area around one of the thin locating bolts. The brass insert became so hot that it melted and carbonised the adjacent plastic. Heat damage spread a few mm to either side before the switch finally either 'blew up' or simply burnt out internally so stopping the current flow.

In the particular example shown here (from a 2701 with microswitches both sides) the damage is uncharacteristically severe and has led not only to carbonation and embrittlement of the pins but to visible damage of the base-plate also.

In simple terms, the switch in this location got very hot indeed before it finally expired. Internally, the overheating points would have been 'red hot' and with the base plate raised to several hundred degrees centigrade.

In turn this raises the question of a possible fire being started but the heated area is 'contained' within the actuator casing and the risk is small, unless the plastics material of the base-plate itself could be made to catch alight.

Damage as extensive as this is unusual because despite the fact that microswitches overheat very regularly in the 2301 and 2701 series, usually they fail completely and with the current being cut off well before any region of the the base-plate suffers this extent of overheat damage.

Usually, there is no visible damage to the outside of the base-plate. Quite often, microswitches can be replaced and the actuator made serviceable again. Sometimes however, and often in cases where an obviously faulty actuator has been left in circuit for months or years, the locating pins have become embrittled and the base-plate is scrap.

Enterprising homeowners have tried to reclaim their damaged baseplate by drilling out the pins and locating both microswitches using tiny nuts and bolts or nails used as rivets.

Gluing a new switch into position using a powerful sealant adhesive can offer a successful solution in these cases - but it is much easier to obtain a replacement baseplate from an actuator that has been scrapped for other reasons.

In all cases the failure is in the same place. As shown here, the top image is of a boss in good condition, the image to the right shows a crack having appeared (often the brass gear ring jams in one direction when this happens) and in the last image, the 'nib' of plastics material has cracked off completely.

These faults are not repairable. Often however, serviceable central bosses can be obtained from actuators that have failed for other reasons.

The central white boss is in excellent condition but both microswitches have overheated and this has caused embrittlement of the locating lugs on both sides of the actuator (red circles).

Quite often, it is only the left hand switch that overheats and the base-plate can be used to repair a 2301 (which only utilises the right hand switch location). The central bosses are different for 2 and 3 port valves but can be swapped over.

In the special SZ2355 unit, used primarily in the Dunsley systems, the central boss is the same basic design but the slot is rotated through 90 degrees.

Here there has been extensive leakage, witness the deposited of evaporated water and antifreeze/anticorrosion chemicals. Such leakage - amounting to maybe a few drips a week - would have been no problem for a 2301 type actuator.

The remarkable fact about this photograph is that the leakage maybe continued for so many days or weeks before the actuator circuit board exploded. Usually the boards explode a long time before there is any outward sign of leakage and householders may refuse to accept that their valve spindle is leaking.

Ideally, locate actuators ABOVE a horizontal pipe, so that any water leakage may fall away from the actuator. Where the pipe is vertical, an 1801 may be turned so that its cable is at the top rather than at the bottom. No such rearrangement is possible for a 1901 3-port actuator because it must be oriented correctly to direct water into the appropriate outlet ports.

The switch body has become so hot near to the N/C connector that plastic has 'bubbled out' of one of the locating holes. The top half of the locating lug on the baseplate itself had disintegrated owing to excess temperature.

Remarkably, plastic has also 'bubbled out' around the central (N/O)connector that was never carrying any current - and that might have been expected therefore to remain cool.

This NTE microswitch may not have been fitted as original equipment - it may have been a DIY or other replacement.

Yet all around the N/O contact there is distorted previously molten plastic - the explanation is probably that when in operation the N/C contact became so hot it heated up and melted a large volume of plastic casing material - and this heat was transferred into the N/O contact before the switch failed completely. This would have happened when the movable contact flipped down and the current was disrupted.