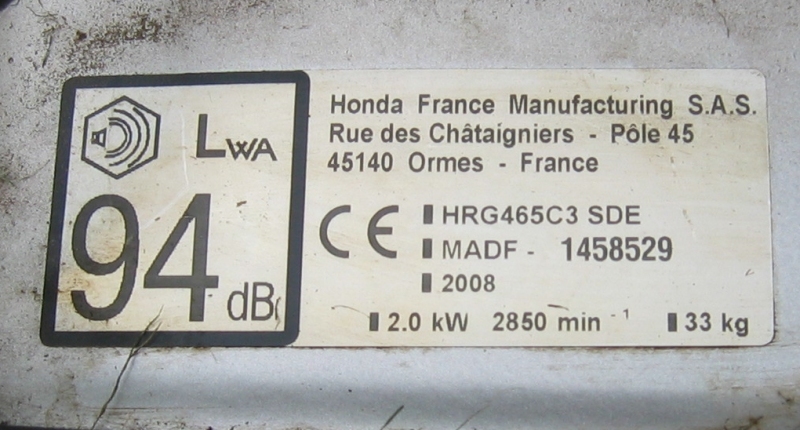

This one has a dB rating of 94 - which is very considerably quieter than many machines that are rated at 97 dB.

It was manufactured in 2008 and probably neglected all its life. It as given to me in early 2022.

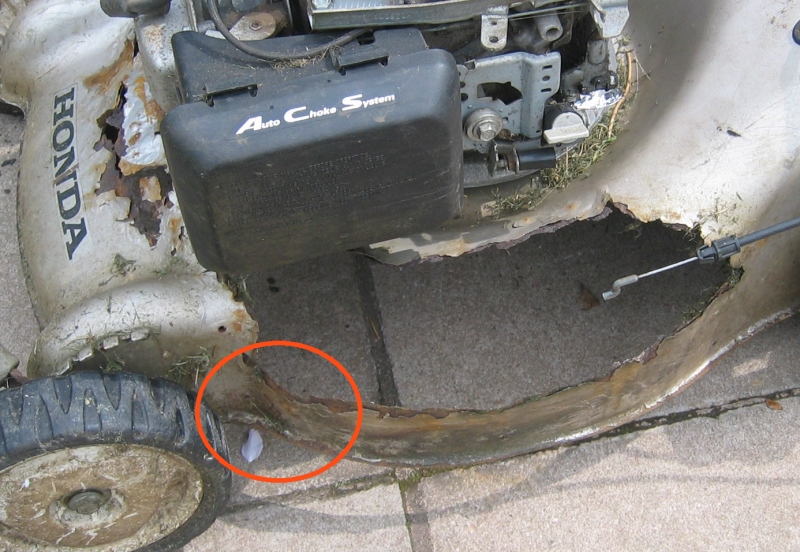

Some pictures of Honda Izy mowers for sale on eBay show the complete front axle and deck section detached from the main body. In these cases only careful TIG welding would likely suffice as a repair.

On the mower shown, the area circled in red was (fortunately) still adequately strong - it served at least to hold the front and rear sections of the deck together!

The repair aimed to enhance the strength of the deck in this critically stressed area.

This again served to keep the front section properly aligned with the main body of the deck.

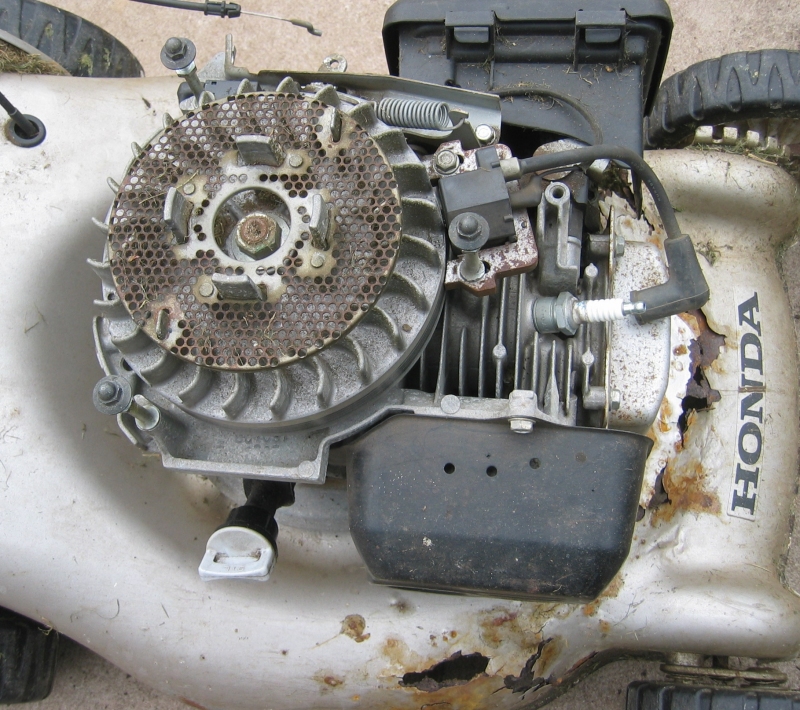

The plug shown is for topping up the oil level - although the units are considered sealed for life.

Never throw anything away - you don't know when it might come in useful.

it was judged that hammering off some of the the thick corrosion would best be done after the deck had been reinforced by the repair patches.

I usually have several tubes of this available - I used it to build my own garage and later my conservatory many years ago, and I am always finding new uses for it! It sets in about 5 minutes, bonds very well to metal and concrete, and is immensely strong.

Thick corrosion has been removed by hammering and then the surface cleaned with a power wire brush and solvent.

Not all the resin filler and fibreglass patches have yet been applied.

Long rivets were used to extend through the thickness of resin (3mm in some areas) and also through the stainless steel washers shown.

The curves were formed by hammering the repair panels around lengths of steel tube 50 and 75m diameter.

Some of the rivets are shown in place.

One of the most difficult jobs was drilling the metal deck of the mower. The steel was so hard it blunted ordinary HSS drills so I had to buy some 4mm diameter cobalt drills - and those were little better. Several of them snapped and others needed sharpening every few holes. I sent them back to the eBay seller - complaining that they were of insufficiently high quality.

Some types of 4-stroke petrol mowers must not be turned onto either side - only tilted backwards on their rear wheels. This again is to prevent excess oil getting into parts of the engine where it could cause damage!

Generally, 4-stroke mowers can be tipped onto the side containing the oil filler. This is a standard way of draining the oil in designs where no drain plug is provided.

Some petrol types (including the model shown here) must only be tipped up as shown, never onto their sides. The handle can be wedged beneath a convenient exhaust pipe!

This gives safe access for judicious use of a hose pipe to remove all accumulated grass and soil from the underside.

Ideally, the blade should then be smeared with oil after being allowed to dry.

It did misfire and stall several times during its first outing, but this was likely caused by a partially blocked fuel filter located in the base of the tank.

Repair costs:

Rivets £4

Washers £2

Metal primer £2

Cobalt drills - £0 (refunded via eBay)

Gloss paint - £0 - an old can destined for scrap.